WALTER Keel Coolers

For more than 70 years, Walter Keel Coolers have proven to be the most dependable, trouble-free and economical form of marine engine cooling.

The rugged design and longevity are proven by decades of service on US Navy vessels, US Coast Guard vessels, workboats, fishing boats, ferry boats, supply boats, tug boats and pleasure yachts throughout the world.

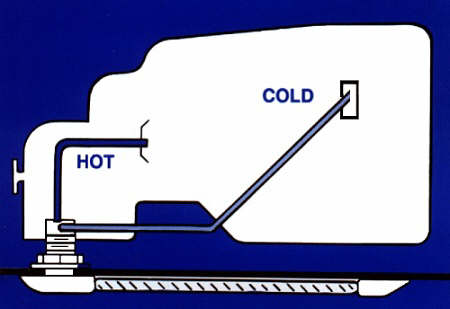

Completely CLOSED-LOOP freshwater engine cooling for trouble-free operation of every marine engine (propulsion, generator and auxiliary)

Lower fuel costs and extend engine life

Eliminate costly downtime from raw water pump failures and clogged sea strainers

Prevent salt, silt and debris from getting into the engine jackets, increasing engine life and reducing maintenance costs

Operate in freezing temperatures without the need to drain the cooling system.

Unlike inboard heat exchangers, Walter Keel Coolers require no seawater inside the hull

Proper engine cooling protects your engine investment and allows the engine to run more efficiently:

SAVE $ on fuel and coolant costs

REDUCE / ELIMINATE downtime and operate trouble-free

SAVE $ on annual maintenance

FAST DELIVERY - Hundreds of Sizes and Three Models

Walter Keel Coolers are available in three models & hundreds of sizes to suit every application from 10 horsepower auxiliary engines to 2,000+ horsepower propulsion engines.

End Model, Double Stem Model and Center Models to fit every hull.

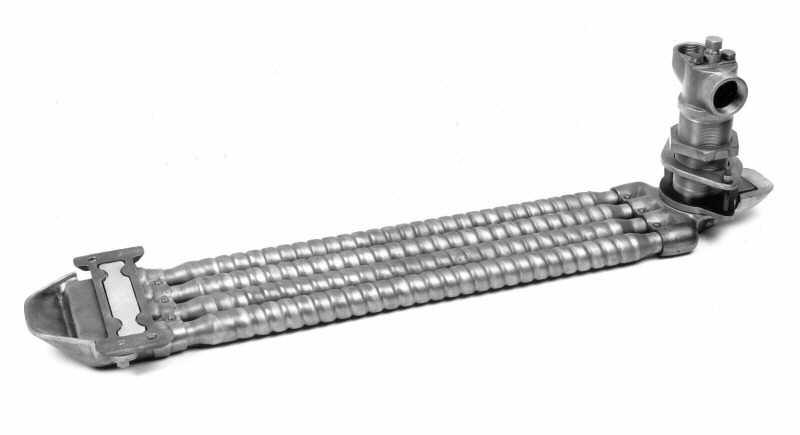

End Models

Unique design with only one thru-hull fitting, WALTER "End Model" Keel Coolers make installation fast and inexpensive by greatly reducing inboard plumbing. The single thru-hull fitting, located at only one end of the cooler, contains both the inlet and the outlet.

The Return End Fitting can be located under a fish hold or other area inaccesssible from inside the hull, greatly increasing the available hull locations for mounting.

It's no surprise that boatbuilders and shipyards prefer WALTER "End Model" Keel Coolers.

Available in 2, 4, 8, 12 and 16 tube configurations; the 12 and 16 tube coolers consist of a "double stack" to provide the maximum amount of cooling in the most compact assembly possible.

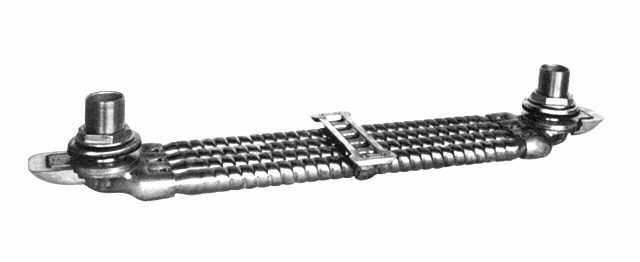

Double Stem Models

The most economical Walter Keel Cooler, "Double Stem" Models have one thru-hull fitting at each end of the keel cooler. The thru-hull fittings feature standard male pipe threads for easy connection with standard pipe fittings.

Available in 4, 6, 8, 12 and 16 tube configurations; the 12 and 16 tube coolers consist of a "double stack" to provide the maximum amount of heat exchange in the most compact assembly possible.

Walter Turbo Tube - Maximum Heat Exchange and Strength

PREMIUM Walter Turbo Tube is made of CUPRONICKEL for the perfect combination of:

Maximum heat exchange

Maximum strength

Maximum corrosion resistance

Turbo Tube features spiral grooves on the outer wall and ridges on the inner wall to continually propel and swirl the coolant against the inside tube wall where the heat exchange takes place.

The unique turbulating action of Walter Turbo Tube exchanges much more heat than smooth rectangular or round tubes in which most of the coolant flows through the center of the tube, only occasionally contacting the tube wall.

Because Walter Turbo Tube provides so much more heat exchange, a more compact and inexpensive Walter Keel Cooler can be used.

Streamlined and Foul-Proof Design

Walter Keel Coolers are streamlined, unlike boxy rectangular-type coolers which create drag. In comparison, streamlined Walter Keel Coolers can be mounted flush with the hull and do not need to be recessed, greatly simplifying installation time and expense.

Due to the space between the hull and the round tube surface, seawater circulates between the round tubes, continuously washing debris from the cooling surfaces -- unlike rectangular tubes which can become clogged with mud and debris.

Demountable Design

The unique DEMOUNTABLE design allows Walter Keel Coolers to be quickly removed for hull maintenance without disturbing the inboard plumbing (the thru-hull fitting can be left in place on the hull). In an emergency, the demountable design allows the Walter Keel Cooler to be removed with the vessel in the water, should a drydock be unavailable.

No Brazed Joints to Crack and Leak

Walter Keel Coolers are engineered with FLEXIBLE double o-ring aircraft-type pressure seals which have proven reliable for decades in tens of thousands of installations, including US Coast Guard and US Navy vessels.

This flexible design eliminates the problem of brazed joints cracking in heavy seas as the hull flexes or during a hull impact (as with a tug boat or pushboat). Walter Turbo Tubes can accommodate moderate hull curvatures.

Computerized Machining and Old World Craftsmanship

The Walter Machine Company combines 90+ years of old-world craftsmanship with the most advanced computerized (CNC) machining in the manufacture of each Walter Keel Cooler.

Precision components combined with a superior design results in long term reliability you can count on.

Computer-Aided Engineering

Computer-aided custom recommendations combined with over 70 years of EXPERIENCE ensures an accurate keel cooler sizing based on the specific operating characteristics of your engine and vessel. Walter Keel Coolers are time-tested on US Coast Guard vessels, US Navy vessels, commercial fishing boats, tugboats, pushboats, large pleasure yachts, and even small sailboats.

In Stock for Immediate Shipment

Walter Machine stocks hundreds of keel coolers, most available for IMMEDIATE SHIPMENT.

Keel Cooler Sizing Requests

For a free quotation, please fill out and email to info@waltergear.com or fax 201-656-0318

Request for Keel Cooler Sizing

Request for Keel Cooler Sizing (pdf)

Request for Keel Cooler Sizing (word document)

Keel Cooler Information

Keel Cooler Parts Diagram (pdf)

Keel Cooler Zinc Anode Chart (pdf)

Keel Cooler Cleaning Suggestions (pdf)